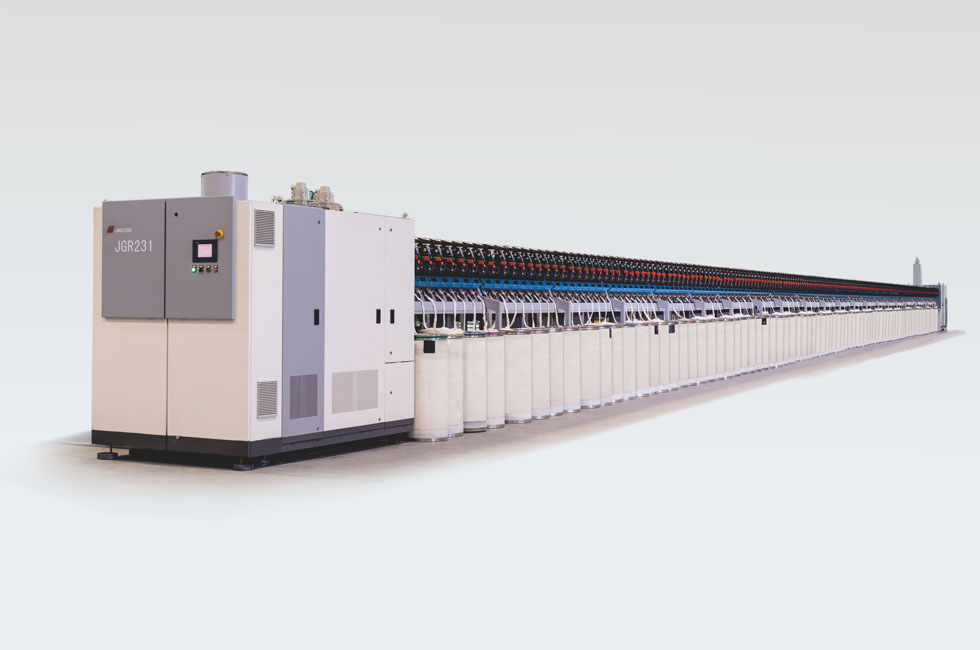

Air Jet Spinning Machine, Air Jet Spinning Process

What’s Air Jet Spinning?

Air-jet spinning is also known as Vortex or fasciated yarn spinning. Before the sliver from the drawframe is supplied to the air-jet spinner, combing is often used, as it is imperative to get rid of any dust or trash that could obstruct the spinning jets. Twist is inserted to the fibres, mostly on the yarn surface, by the vortex created in one or two air-jet nozzles. The resulting yarn consists of a core of parallel fibres and a sheath of wrapped (twisted) fibres. The yarn produced by air-jet spinning resembles a ring-spun yarn but is not as strong. The yarns are also inclined to shrink. High delivery rates of 150–450 m/min are possible with this technique.

The feed material, i.e. the slivers, is fed to the four-roller drafting arrangement. The fibres come out of the front rollers, are sucked into the spiral orifice at the entrance of the air-jet nozzle, and are then held together more firmly as they move towards the tip of the needle protruding from the orifice. At this stage, the fibres are twisted by the force of the air-jet stream. This twisting motion tends to flow upwards. The needle, which acts as a guide on the needle holder, projects towards the inlets of a hollow spindle. A nozzle block provides a swirling air current, which acts on the drafted fibre bundle. The needle protruding from the orifice prevents this upward propagation (twist penetration). Therefore, the upper portions of some fibres are separated from the nip point between the front rollers, but are kept ‘open’. After the fibres have passed through the orifice, the upper portions of the fibres begin to expand due to the whirling force of the air-jet stream and twine over the hollow spindle.

The fibre bundle is then sucked into the hollow spindle, and twist insertion starts when the fibre bundle is subjected to a compressed air vortex as it enters the spindle. Twist propagation towards the nip of the front rollers is prevented by the guide members acting as the centre of the fibre bundle. On leaving the guide member, the whirling action of the air current separates the fibres randomly towards the bundle.

The leading ends of all the fibres are held into the body of the yarn being formed, while the trailing ends leaving the front roller nip set are whirled up in the air and are inverted and separated from each other at the inlet of the hollow spindle. The leading ends are less subject to the air current as they are moved around the guide member towards the inlet of the spindle and converted into spun yarn. The fibres twined over the spindle are whirled around the fibre core and made into vortex yarn as they are drawn into the spindle.

The finished yarn is wound onto a package after any defects have been removed. The final package is then removed automatically. The leading ends of the fibre bundle are drawn into the hollow spindle by the fibres of the preceding portion of the bundle being twisted into a spun yarn. The trailing ends of the fibres are inverted at the inlet, separated from each other, and exposed to the swirling air blown through the nozzles. The trailing ends of the fibres are thereby caused to twist around the porting of the fibre bundle being converted into a spun yarn.

Some fibers, particularly those at the edges of the ribbon, will not be subjected to the full twisting action imparted to the main body of fibers by the downstream air-jet. Hence they receive less twist than those fibers in the main bundle. When the yarn gets untwisted in the downstream of the twister, the low twist edge fibers get untwisted to a greater degree than their original twist. Therefore they are given a true twist in the direction opposite to that of the upstream twist.

The main body of the strand will be untwisted into parallel fibers, forming the core and these will be wrapped around by the edge fibers forming the wrapper fiber layer or the sheath, thus forming a fasciated yarn.

The function of the back nozzle is to enhance the cohesion of the strand thus giving greater yarn strength.Since the direction of airflow in the back nozzle is opposite to that of the front nozzle, the back nozzle tends to untwist the wrapper fibers as they are formed inside the front nozzle. This increases the length of wrapping, thus improving the yarn cohesion.

The air-jet spun yarn consists of an untwisted core of parallel fibers and a surface wrapping of fibers. The core fibers account for approximately 85-95% of the yarn mass. The surface wrapper fibers are helical in nature unlike the wrapper fibers in the rotor yarn.

The wrapper fibers are not uniformly distributed over the length; sometimes they are more on the surface and sometimes very few are on the surface. Their frequency and tightness being influenced by the fiber physical properties and the spinning process parameters. “The high level of constriction of the straight core fibers by the surface wrapper fibers results in high bending modulus of air-jet yarns”.

Spinning

Polymer that is to be converted into fibre must first be converted to a liquid or semiliquid state, either by being dissolved in a solvent or by being heated until molten. This process frees the long molecules from close association with one another, allowing them to move independently. The resulting liquid is extruded through small holes in a device known as a spinnerette, emerging as fine jets of liquid that harden to form solid rods with all the superficial characteristics of a very long fibre, or filament. This extrusion of liquid fibre-forming polymer, followed by hardening to form filaments, is called spinning (a term that is actually more properly used in connection with textile manufacturing). Several spinning techniques are used in the production of man-made fibre, including solution spinning (wet or dry), melt spinning, gel spinning (a variant on solution spinning), and emulsion spinning (another variation of solution spinning).